題-4.jpg)

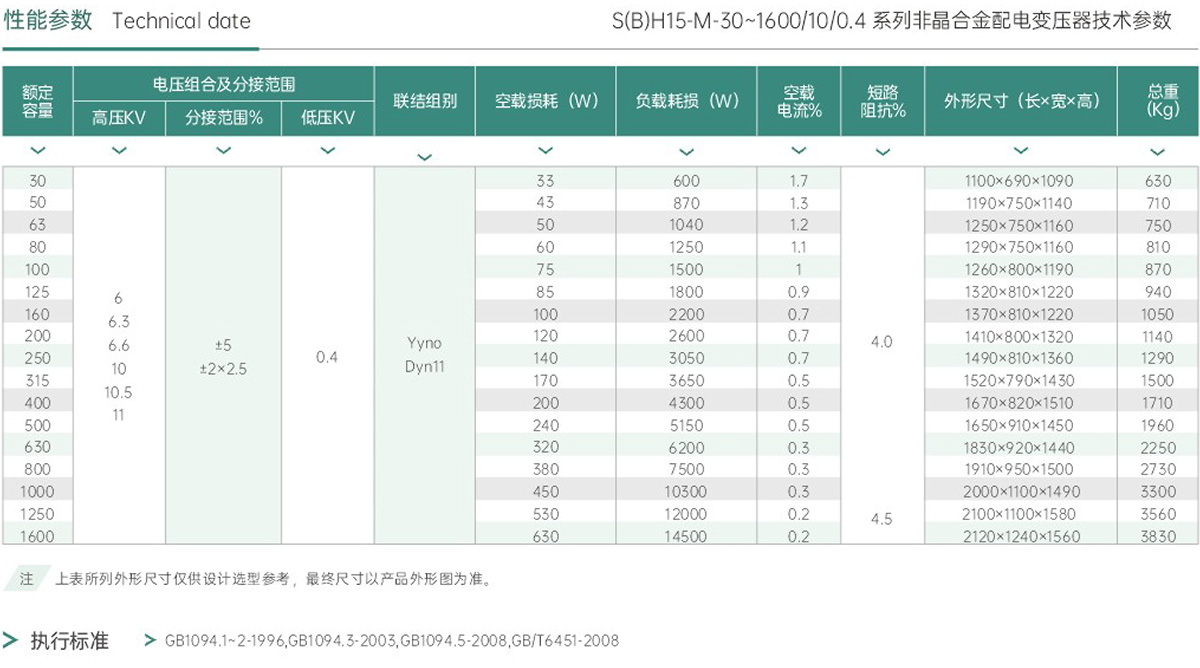

Amorphous alloy iron core has the characteristics of strong magnetic induction, low loss (equivalent to 1 / 3-1 / 5 of silicon steel sheet), low coercivity, low exciting current and good temperature stability. The no-load loss of transformer made of amorphous alloy iron core is only 1 / 4-1 / 5 of that of current S9 products, and the no-load current is 60-70% lower than that of S9 series, which is very energy-saving. It is especially suitable for users with low load rate, such as rural areas and developing areas. S (b) H15 amorphous alloy products and iron core adopt single frame or three five phase five column wound iron core. The iron core is clamped with thin plate forming frame structure. The low-voltage coil is foil wound, so that it has low loss, strong short-circuit resistance, advanced and reasonable structure, and the overall performance index has reached the world advanced level.

Maximum ambient temperature 40 ° ℃ maximum daily average temperature 30rc

The maximum annual average temperature is 20 ° C, and the minimum temperature is - 25 ° C

Transformers operating under special service conditions can be provided according to user requirements.

Product features:

The transformer core is made of amorphous alloy strip, and the no-load loss is about 75% lower than that of S9 transformer. The low-voltage transformer adopts copper foil coil to enhance the ability of the transformer to withstand short circuit.

Dyn11 is adopted for transformer connection group to reduce the impact of harmonic on power grid and improve power supply quality. The oil tank and the tank cover are welded into one full sealing structure to prolong the service life and avoid maintenance.

The transformer adopts vacuum oil injection, which can completely eliminate bubbles in the coil and ensure stable insulation performance.

Full wave lightning impulse test with peak voltage 25% higher than the national standard shall be carried out before each transformer leaves the factory to ensure the safe and reliable operation of the transformer.